You are not logged in.

- Topics: Active | Unanswered

#1026 12 Aug 2022 5:22 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

You’ll have fun with ‘em on Chuck! I think it’s safe to say that….

Meanwhile I’m fairing in the lead brick I glued into my daggerboard. There’s an interestingly appropriate thread over on the WoodenBoat forum about a fellow asking about making one from stainless (NOT for a Waterlust though) that touches on the physics of boards & ballasts:

Offline

#1027 13 Aug 2022 7:28 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Waterlust sailing canoe in Norway

Good luck Chuck, looks great!

Re. Daggerboards. My observations are:-

1. Stainless steel is a waste of money. My mild steel one (primed and painted) is fine. I just touch it up when some bare metal shows. It would be different if the boat was kept in the water all the time, when I would have it galvanised.

2. In my view the 'lift' advantages when tacking of a foil shape are more than outweighed by the lack of drag as a result of the steel board being 8mm thick rather than 20mm.....But then I tend to pedal/sail upwind!

Offline

#1028 13 Aug 2022 11:44 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 138

Re: Waterlust sailing canoe in Norway

Wow. That outrigger makes a huge difference! With it the Waterlust can be sailed without a death grip on the tiller and sheet, and you can even relax a bit. I set the boat up on a close reach and didn't touch the tiller for two miles, making minor course corrections with the mizzen.

On the other hand, there is some loss of 'feel' to the boat with the outriggers. And, on a beam reach with the waves hitting amidships, first one ama rises causing the boat to roll, and then the other one hits the water with a thud, so it can be a little bit of bouncing back and forth depending on the conditions...

I found out today that other boats like the Laser and O'pen Skiff have bolt-on foil kits (also see the Michael Storer page on foil experiments on his boats), and of course my mind started wondering about a foiling Waterlust...

Last edited by Chuck (13 Aug 2022 11:48 pm)

Offline

#1029 14 Aug 2022 12:10 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

You were out alone with your amas and no ballast Chuck?

I still hold that this design is intended to be loaded to some degree beyond just a single hand's weight. Otherwise that 'death grip' is pretty much a mandatory accessory!

Be interesting to learn how adding a jib affects what you call 'feel'! Adding the wetted area of an ama down on the water certainly changes the dynamics of how the thing behaves... that was the point after all. Their addition doesn't add much weight but the added buoyancy greatly reduces tendency to roll to leeward.

I'm fairing my d'board this w/e after epoxying in a 10 lb /4.3kg lead brick. Making progress on additional lead ballast 'carrier' that will fit into the bottom of the storage well between mast pockets. Anxious to learn how the additions affects stability, whether I have additional 'dry' ballast aboard or not.

And those foiling links...

https://www.glidefree.com.au/open-bic-foils/

https://www.storerboatplans.com/category/foils/

https://sail1design.com/foilsz-laser-il … -with-s1d/

https://www.storerboatplans.com/foils/s … est-of-us/

@ ~ 130 lbs a Laser's not much more than a Waterlust, so you may be on to something....

Last edited by spclark (14 Aug 2022 12:23 am)

Offline

#1030 14 Aug 2022 4:39 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 138

Re: Waterlust sailing canoe in Norway

I was out with crew and 60# of ballast.

One nice perk of a crew is to take on peddling duties during lulls

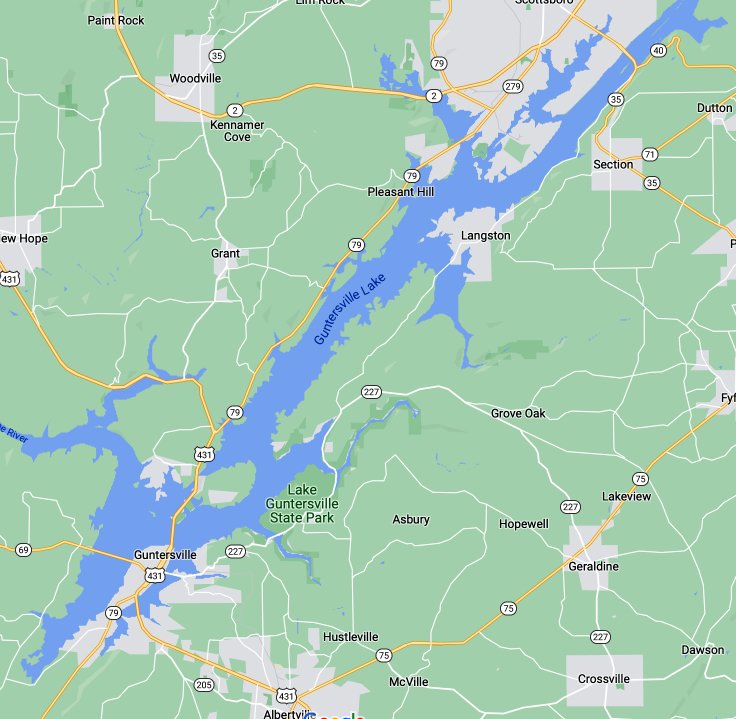

The docking arrangements for the Waterlust with outrigger are a bit unusual, but luckily we showed up before the happy hour rush and found some room. You can see that with the amas and the ballast in the main compartment the boat sits by the head. The initial launch was off a trailer with a ramp wide enough to accommodate the aka already lashed on, and crew held both painters with the boat downwind so we didn't have to worry about tying up to a dock. This area of Alabama is experiencing quite a bit of growth, and this waterfront area on Lake Guntersville just opened up within the past year.

It makes for a great place to get lunch and a beer before sailing back again!

We did about 13 miles over a leisurely 7 hours.

The different sense of 'feel' with the outriggers is that there is less rolling and moving in response to every puff since the ama constantly in the water stabilizes things. Without the amas, one is always moving, shifting, steering, and playing the sheet constantly, and most of the input comes by the seat of your pants, giving a lot of feel.

Last edited by Chuck (15 Aug 2022 2:49 pm)

Offline

#1031 14 Aug 2022 5:54 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

Thanks for the details Chuck! Very informative report out of your venture Friday. Everything you've described confirms my thinking on what adding ballast ('moveable' or fixed, in any combination) and the amas does for making a Waterlust more amenable to a pleasant day's outing rather than an exciting 'ride on a thoroughbred' when every moment may be thrilling!

Details on my ballasting plan as envisioned currently allows up to 75 lbs of lead, strapped to a carrier board that's secured in the compartment between mast pockets. Different lead 'bricks' can be added or subtracted as well as located slightly differently depending on what spot on the carrier they occupy. This is all done before launch of course, too tricky to do once underway. The weighted daggerboard is a constant (I may make a solid wood one over the winter) though, and the additional weight 20" below the hull's bottom ought to help slow rolling moment in that it ought to act to counter weight of spars & sails above.

Another 'improvement' I'm adding is a tiller extension joint from Ronstan that eliminates the uncertain nature of a cordage lashing at the expense of eliminating the ability to rotate the extension 90° which to me seems like a reasonable compromise. The joint allows for removing the extension for transport and storage.

That lake looks to be a wonderful asset for you! I hope it's close by, that you don't have a longish drive to get there & back!

That along much of its length it's nearly two miles in width leaves a lot of room for extended headings, something I have yet to experience. So far the lakes I've been out on have been fairly small, but larger bodies are close enough they're on my list.

All in all a welcome read your post. Thanks for sharing!

Offline

#1032 15 Aug 2022 9:46 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Waterlust sailing canoe in Norway

Very interesting reading. Thanks chaps! (I won't personally be going down the foil route but I will watch with great interest if any of you do!)

One thought on the stability/ballast issue.My steel daggerboard is a huge help, but it is unwieldy especially if shallow water is encountered.

Has anyone considered leeboards? They could swing up and down easily. The weight (lead) could be applied low down on the board and they could even be detachable to reduce weight when off the water.

Offline

#1033 15 Aug 2022 12:36 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

The 14' stripper scow I built some fifty years ago featured leeboards. Both were about the same size and shape as the d'board in our craft. That design's cockpit was a little shallower than ours (before I took floors out, even less!) while also being over twice as wide. Both boards had trunks into which they'd pivot into, the idea being only one was needed depending on what side the wind was coming from.

Leeboards have their place in sailing canoes. They were commonplace back a century ago when many earlier designs were in use. Certainly they could be retrofitted to a Waterlust, at least externally - something to be clamped on the gunwales as desired - so there's merit in your suggestion MartinC. Were one to contemplate a Waterlust II design such an endeavor would see an immediate increase in cockpit space at the expense of weight gain from incorporating two board trunks, one on either side of the cockpit.

I have yet to learn what effect adding lead weight to my d'board may provide; with a total weight significantly less than your steel one I'm hopeful it's not going to be too awkward in use. The shallow water risks from having a rigid fin extending down some 30" beneath the hull must always be kept in mind! Encountering a submerged obstruction with the board down despite (or perhaps because of?) as substantial a board trunk as we've fabricated in our boats isn't something I want to dwell upon long.

Those pivoting lee boards in my scow would tilt back had I struck something with one, be less likely to do permanent damage to hull or occupants. But I can see purpose in putting a hole or two into a d'board if one expects to encounter shallow draft conditions, something that could be useful in keeping a d'board at a lesser depth if necessary.

Offline

#1034 15 Aug 2022 2:56 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 138

Re: Waterlust sailing canoe in Norway

Hi Martin,

I think leeboards are an interesting and useful idea, but I don't know how differently they would perform while sailing. Hugh Horton in Cedar Key, Florida advocates for them on his sailing canoes for the reason you mention: they tip up automatically when running over shoals, like the hard oyster bars he has in Florida. His design has only one, which goes down outside the hull on the port side. So, no case and assymmetric. A very interesting take on control surfaces for these boats is how Frederick Fenger built his sailing canoe that he sailed up almost the entire island chain in the Caribbean: no rudder at all! He just shifted his weight and manipulated his board(s?) to steer the boat.

My experience during my last sail on the lake is that I had to raise the board and rudder over 20 times to clear all the aquatic vegetation we would snag (Vallisneria, known colloquially as eelgrass). Sailing into a bed of that stuff was like sailing into molasses.

Hugh's pages show some of the interesting mechanisms he devised/collected for raising/lowering a leeboard, including a really neat looking conical clutch made out of carbon. I saw this boat at Cedar Key when I was there in May, and may have some pictures...

On another topic, I found myself working on the jib rigging last night. I have three (!) additional lines to try to figure out how to run on the deck, while accommodating both mast steps. It is quite complicated -- I almost need a theodolite to run all the angles to make sure things clear each other. The additional lines are a jib halyard, a jib downhaul, and a line for lazy jacks. Add to that the main halyard, downhaul, and anchor lines and it is beginning to look like a spider web up there. The same fairleads serve different purposes for different lines depending on which step the mast is in, etc. The setup would need an instruction manual for anyone else to setup. As much as I like stuff like that, I hope it doesn't add too much time to setting up the boat, which already takes longer than I would like. One of my next tasks is to see if I can unstep the masts, bundle them with the sails and stow them in the cockpit for trailering with the lines still run. If that is possible, it would save a LOT of time rigging. It would be interesting to compare pictures of the boats with everything stowed for trailering...

Last edited by Chuck (15 Aug 2022 3:21 pm)

Offline

#1035 15 Aug 2022 3:26 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

One of my current ‘neatifying’ goals is same as to rigging & trailering mast fully ready to step once at a launch site. (Wastes a LOT of time having to run then sort everything before stepping mast!) Some kind of sailbag arrangement may be helpful with this, keep everything wrapped tight against wind & water while trailering.

I'm adding a second set of main reef cleats (replacing originals w/smaller in SS too) so as to make reefing easier when main’s stepped forward. First reef’s cleats'll serve as fairleads for lines that lead back to second reef’s cleats, well within reach from center of cockpit.

(BergenGuy I hope you're well & enjoying your Norway summer with the Waterlust that inspired you to start this forum! You haven't been posting much here recently, I'm looking forward to seeing more reports of your adventures!)

Last edited by spclark (15 Aug 2022 11:33 pm)

Offline

#1036 17 Aug 2022 11:40 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

And just in time to add some background info to Chuck’s research -

Offline

#1037 17 Aug 2022 4:09 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Waterlust sailing canoe in Norway

What an excellent video. Thanks SP.

Offline

#1038 17 Aug 2022 6:50 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

My pleasure MartinC! I learned of that after receiving an e-mail from the Waterlust folks in Miami this morning. Their inspiration gave CLC the project that we’ve become so enamored with; I felt it would be of wider interest to the forumites here, even if it’s on a divergent tack….

Offline

#1039 19 Aug 2022 10:51 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 138

Re: Waterlust sailing canoe in Norway

A building question for the group:

What are your thoughts on attaching fittings to the deck with screws? I know that the best practice for through holes is drill-fill-drill. Is this also necessary for screws that bite into the material? Ie, do screws hold in epoxy? As an alternate technique to prevent water from reaching the wood, could one just butter up the screw with epoxy and then drive it into the hole?

Offline

#1040 20 Aug 2022 12:26 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

The Gougeon Brothers solved this question decades ago Chuck.

Their experience is summed up in this section of the WEST System web pages:

https://www.westsystem.com/instruction- … -hardware/

and -

https://www.epoxyworks.com/index.php/hardware-bonding/

Mike Waters has added some additional engineering details for bonding fasteners into ply and solid wood also:

https://smalltridesign.com/Trimaran-Art … dware.html

Here's Mike's thinking on foils -

https://smalltridesign.com/foilers-take … 02021.html

and -

https://smalltridesign.com/Trimaran-Art … foils.html

Then there's a blog I just discovered this evening, with a post about our very own -

http://smalltrimarans.com/blog/waterlus … utriggers/

Last edited by spclark (20 Aug 2022 3:15 am)

Offline

#1041 21 Aug 2022 6:04 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Waterlust sailing canoe in Norway

Very interesting links SP. Thanks.

I have found that for small boat sailing (and the Wasterlust is a very small boat!) where the loads are very light, screws (or through bolting if you can reach) are perfectly acceptable, as long as you support the deck with a reasonable backing plate. I always over-size the hole just through the epoxy so the screw is not pulling on the epoxy layer as otherwise it will tend to crack it, and use a mastic sealant on the screw to prevent water penetration.

My experience in building anything (houses,cars,boats) is that everything fixed will one day - and probably sooner than you think - need to be removed. For this reason I very rarely epoxy screws/bolts in, as nothing is forever!

The modern philosophy is to make one time fixtures and then to scrap the whole thing when you want to change a component, but I prefer the centuries old wisdom of building in such a way that all the parts can be easily replaced.

Offline

#1042 21 Aug 2022 6:23 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

Martin I echo your sentiment about "permanent" not always being so. Haven't driven a nail in years in preference for what here are called construction screws. More holding power, can be used indoors or out w/o fear of rusting, and their TORX drive heads seldom if ever get stripped. And should the need arise they're easily removed, often good as new for re-use later.

With that philosophy in mind I've engineered a ballast carrier board for my Waterlust out of 1/2" birch veneer ply. It fits through the storage hatch – barely – then is secured to two tabs bonded to the lower hull panels with SS carriage bolts & threaded knobs. In back it's held down by cleats bonded to the second bulkhead. The lead ballast bricks I've cast are secured with 1" webbing fitted with adjustable QD snaps shown here:

I have five remaining; from one to three can be carried, maximum of 75 lbs /34kg if the heaviest are chosen.

I'm presently juggling several tasks towards finishing these 'improvements': bonding the ballast carrier mounts, painting my amas, painting my weighted daggerboard now that it's been faired & finished with a last coat of unthickened epoxy. So once this is all completed, once the breezes of fall return (it's been pretty benign here wind-wise the last few weeks) I hope to be ready to get out & evaluate how all these endeavors will improve my experience with this design.

Offline

#1043 22 Aug 2022 2:11 pm

- Bergen_Guy

- Member

- Registered: 6 Feb 2020

- Posts: 353

Re: Waterlust sailing canoe in Norway

Hiya! Sorry about being so quiet for so long! Summer took over and family holidays etc took over all my brain power. Not so much though that I didn't book the ferry to Denmark to meet up with the Scandinavian chapter of the Dinghy Cruising Association for two days of sailing on the inland (but salt water) Lymfjorden. What a fantastic few days on the water. I took Svale with outriggers and she was just super. A bit like what i imaging going touring in a small open top sports cars, when the rest are in family cars! Anyway, she had a proper work out, I was down to double reefed main and mizzen at one point, and we got some decent sized chop and all I can say is - fantastic - Yes, I do need some actually waterproof trousers if I am going to sit out on the side deck, which I did going upwind in some of the heavier airs, but otherwise it all worked just fine. Yes, I have a few things to do, mostly related to keeping things neat in the cockpit and having some sort of better system for navigation than I currently do. I took lots of video and hope that some others did too - once I get hold of it I will share it here. So far I only have what I took - the view from inside a waterlust being familiar to most of us by now! That and somehow there is water in one of my outriggers - there must be a tiny hole - I needed to put a hole in the top anyway at some point, but I drilled a hole in it to let it dry out as soon as I got home. Not sure if I will just put a bung in, or a proper inspection hatch. I guess the latter is probably good if I can install it without it leaking... Incidentally my normally dry main storage hatch seems to have leaked a bit, admittedly I was taking some good waves over the front, so I guess some was forced around the seal.

The most magial part has to be Sunday morning - where to get back before a forecast of thunder, I left in company with a chap in a Welsford Patherfinder, at 6 am, under a clear sky and with a mostly following breeze - swallows all around, the head of a seal popping up from time to time, the still of the morning gave way to a solid breeze further offshore and we zipped in company for two and a bit hours. The boats very well matched for speed incidentally - I am very impressed with what John Welsford has done there.

Anyway, so great to use Svale for her designed purpose - she performed superbley!

Last edited by Bergen_Guy (22 Aug 2022 2:34 pm)

Offline

#1044 22 Aug 2022 4:16 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

OUTSTANDING Guy!! Welcome back ‘aboard’ & many thanks for the video report!!

Offline

#1045 22 Aug 2022 8:25 pm

- Bergen_Guy

- Member

- Registered: 6 Feb 2020

- Posts: 353

Re: Waterlust sailing canoe in Norway

Chuck, regarding screws, I have taken a similar approach to Martin, and I have drilled slightly undersized holes, and set screws into some sort of waterproof bedding compound. On my side decks I measured carefully and the load bearing screws go into the longitudinal stringers, for other things like the u shaped fittings that I use for most of my cleats, they are either directly into solid wood in the case of the mast, or through a few large ply elements, like the one at the front of the cockpit for the main sheet attachement, or breasthooks for the for and aft ones. I have so far not had any issues - touch wood (or should that be epoxy).

I like seeing the discussion about leeboards - I went as far as getting Hugh Horton to send me a set of plans for Bufflehead, as I am intrigued by the smaller, lighter Bufflehead. I have also sketched and thought about fitting Horton style lee boards to the Waterlust, or ones in cases at the side of the cocktpit (like in the sketches made by John Welsford when someone was trying to get him to draw up a modern 'Nautilus' style sailing canoe - search the web for the sketches and chat - sadly nothing actually got built as far as I know). If you use the forward well for the mirage drive anyway, you don't save much space by having a pivoting board at the side of the cockpit, and you probably loose quite a lot of useful space, the big win would be having it outside the hull. I suspect if done well, the performance aspects are just fine, it's just getting over the idea of having an asymmetrical boat!

On the topic of 'sorting things out' one thing I will do is make some arangement so that I have the mizzen sheet to hand, likely round a block in the deck to a jam cleat that falls easily in the hand when I am sitting in the cocktpit. I suppose I will have to be clever so I leave a good sitting spot on the side deck, or I will get a sore bum when I sit out - maybe I need to be super cunning and have it running through a small hole and inside the cockpit with a cleat placed on its side on the cockpit coaming itself... all stuff to think about. The wood for my hollow mast is still sitting patiently waiting in the garage...

Last edited by Bergen_Guy (22 Aug 2022 8:26 pm)

Offline

#1046 25 Aug 2022 6:38 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 138

Re: Waterlust sailing canoe in Norway

Guy:

Wow! That looks amazing! What a wonderful trip that must have been

Last edited by Chuck (25 Aug 2022 6:39 pm)

Offline

#1047 25 Aug 2022 9:46 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

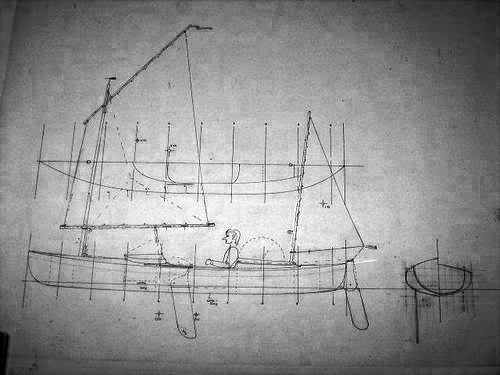

I have also sketched and thought about fitting Horton style lee boards to the Waterlust, or ones in cases at the side of the cocktpit (like in the sketches made by John Welsford when someone was trying to get him to draw up a modern 'Nautilus' style sailing canoe - search the web for the sketches and chat - sadly nothing actually got built as far as I know).

From the (not so) Wayback device:

http://forum.woodenboat.com/showthread. … ling-Canoe

And my attempt at making the included sketch more 'approachable':

Twin weighted bilgeboards (as in that Pumpkinseed scow I built), water ballast capability, reefable from cockpit, 550 lbs displacement (250 liters).

More:

https://www.songofthepaddle.co.uk/new-w … 31536.html

(I'd like to believe DM would have seen this thread when he was researching for CLC's Waterlust commission a few years after it appeared!)

No mention of the design on John's project plans page:

http://www.jwboatdesigns.co.nz/plans/plans.htm#sailing

At least one appears to have been built! http://bills-log.blogspot.com/2011/08/n … canoe.html

Last edited by spclark (25 Aug 2022 9:48 pm)

Offline

#1048 26 Aug 2022 7:06 am

- Bergen_Guy

- Member

- Registered: 6 Feb 2020

- Posts: 353

Re: Waterlust sailing canoe in Norway

Good research there SP! I do wonder how one of those would come out in the flesh - there is almost enough there for the very keen to build one.

I think though that the 'built' Nuatilus on Bill's Blog is to a design by Paul Fisher of Selway Fisher, a 50/50 sailing canoe. (https://www.selway-fisher.com/Sailcanoe.htm)

While I love the Waterlust with its outriggers, I do often look at the elegant simplicity of the single hulled 'variant' of the sailing canoe and think that this craft, were it docile enough would really be the thing. I can see why Martin has gone the way he has.

Anyway, that search for the perfect vessel will rumble on forever I guess. In the mean time I have put up on youtube all my unedited footage from the DCA rally in Denmark, you can find it

https://youtu.be/eZwsGvnFVos

and

https://youtu.be/XzLulMPyJ-Q

I hope to edit it, and maybe splice in something from some of the other attendees - I think Ralf in the Pathfinder also has some video footage of Svale from the outside, which I look forward to seeing when he gets back to civilization.

I am now happily thinking about the small modifications needed to bring Svale up to the next level. Blocks and cleats for a revised sheeting position will soon be on order, and I have now emptied and dried out the leaking outrigger body (it only had a few drops inside, but that's a few drops too many! So I have a few small drain holes to plug and a bung that will go in the top surface so that the 'hull' can be kept 'open' when in storage, and hopefully nice and dry.

A cleat for the mainsheet is another thing on the list, that will go in a vertical orientation on the back of the dagger board case, and obviously only for occasional use, but I would have found it handy while 'cruising' to be able to do odd jobs around the boat, fetching food, tidying a rope here or there, which would have been nicer to have done 'under way' rather than leaving the main flapping while I sort stuff.

A decent sort of Nav station is also in order, possibly something that swings out from under the side decks so that I can keep a folded chart easily to hand, but out of the worst of the spray. I did also find one stupid thing with my compass location, which is that it's on the centreline, and if sailing downwind with the board up, I couldn't see it very easily! It's fine with the board down - ah well, I don't think I am about to move it now. My mesh, cockpit tidy at the front could also easily be twice the size.

Plenty to be getting on with on wet and rainy days. I do enjoy having something like this to think about - gives me something to chew over in those quiet moments when not much is going on!

Last edited by Bergen_Guy (26 Aug 2022 7:07 am)

Offline

#1049 26 Aug 2022 11:18 am

- Bergen_Guy

- Member

- Registered: 6 Feb 2020

- Posts: 353

Re: Waterlust sailing canoe in Norway

A bit more eye candy for waterlust lovers from others on the recent rally in Denmark.

Here I am flying off the wind, just fantastic.

This one grates a bit as its a lovely portrait, but I can't really enjoy it, as I have the main oversheeted to keep the speed down as I wanted to chat with the others, which looks horrid to me!

Offline

#1050 26 Aug 2022 11:25 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Waterlust sailing canoe in Norway

Guy what have you contrived to keep your d’board up going with the wind? I have some trepidation over weight I’ve added with so little real experience in use. With that scow the leeboards were mostly up headed downwind but as beamy as it was it didn’t roll much. Our 36” beam doesn’t roll much with the board up?

Offline