You are not logged in.

- Topics: Active | Unanswered

#1 13 Aug 2020 9:42 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Wood Duck Double Hybrid - Twisted Bow

I am building the 14 ft Wood Duck Double Hybrid kit. All went well with the hull until I closed up the bow, cemented it and then discovered it has a twist in it (see photos). I took great care to set up a level construction platform and checked there was no twist between the front and rear bulkheads while I was wiring it up. The bow took a lot of effort to close up, I used more clamps than shown in the manual and extra wire-holes. My problem is, how to correct it? I could use a fine saw to cut down the bow through the big epoxy fillet, maybe all the way back to the fore bulkhead, but how to keep it straight while I redo the holes, etc? It's almost like the upper and lower panels on the left have a different stiffness than on the right. The factory is on holiday this week, otherwise I'd have asked them first.

Offline

#2 14 Aug 2020 10:15 am

- Ian

- Employee

- Registered: 24 Nov 2014

- Posts: 103

Re: Wood Duck Double Hybrid - Twisted Bow

Sorry for going on holiday just when you wanted our help! We try to stagger our holidays where possible, but it's been a strange year. We'll be back on Monday.

In the meantime, it would help us to work out where the problem lies if you could post a photo of the boat upside down, looking directly in line with the keel and showing the full height of the bows as well as part of the keel line, so we can see clearly at what point the hull starts to go out of symmetry. Preferably with the clamps off, so we are seeing its 'relaxed' shape.

Cutting the fillet, as you have suggested, is one option but you would have to scrape or sand the epoxy off both surfaces before they would meet again properly. It would be useful to know whether you plan to paint the hull or varnish it because it can always be filled and faired if you are painting.

Offline

#3 14 Aug 2020 1:47 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Thanks for the quick reply Ian. Here is the photo requested. The twist starts just forward of the fore bulkhead.

Keith

Offline

#4 14 Aug 2020 2:53 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Forgot to say, I'm planning to varnish it.

Keith

Offline

#5 17 Aug 2020 10:13 am

- Ian

- Employee

- Registered: 24 Nov 2014

- Posts: 103

Re: Wood Duck Double Hybrid - Twisted Bow

I've just been discussing this with my colleagues and we think it will be possible to untwist the bottom panels if you cut carefully along the keel from mid-way up the bows (where the bottom panels meet the side panels) back to where the twist starts. The side panels will remain glued to the bottom panels and to each other, so should hold everything together, though you might want to put the wires back in along the seams as they approach the bows, just in case (I'm assuming the seams are only tack-welded at this point).

I'd drill a few small holes in the keel to get started with a hacksaw blade or similar. Once the cut is made, something thin like a paint scraper can be slid into the cut and used to help lever the panels so that the edge of the starboard panel slides forwards past the port panel -- this should straighten up the keel. Don't worry if one panel protrudes slightly beyond the other, as long as the shape looks right: the edges will be rounded over later. You'll probably have to scrape/sand away some of the fillet to widen the saw cut on the inside so that the panels come together tightly on the outside.

It isn't an easy job, but I think this is the only way to do it while preserving the appearance for varnishing. The wood will be harder to bend now that the epoxy has set it in shape; careful use of a hot air gun may help with that, if necessary, but can scorch the wood if held close for too long. No boat is absolutely perfect, so just try to get it close enough that nobody will notice.

I think the problem may have been caused by the F-clamps holding the bottom panels together. The weight of the clamps provides quite a lot of leverage, which is consistent with the direction of the twist. Spring clamps may be enough this time, since the panels will still be held in place by the uncut seams with the upper panels. Otherwise, put the clamps on the other side so that their weight will tend to correct the twist.

Good luck, and let us know how it goes.

Offline

#6 17 Aug 2020 9:55 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Thanks for the detailed advice. I thought I would have to cut right up to the peak of the bows and between the top and side panels, but I'll try your method first.

I'm separated from my kayak for a couple of weeks right now, but I'll post again when I've tried it.

Thanks again,

Keith

Offline

#7 6 Sep 2020 9:08 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Well, I came back from 3 weeks away and tried to implement the advice above. I first cut open the bow along the keel-line from the front bulkhead to the join between the upper and lower panels, but that left it too stiff to even attempt to twist it straight. Then I cut right up to the top of the stem so the two sides were completely free. Instead of drilling/sawing to make the cuts, I used a multi-tool like this because the internal fillets were really thick;

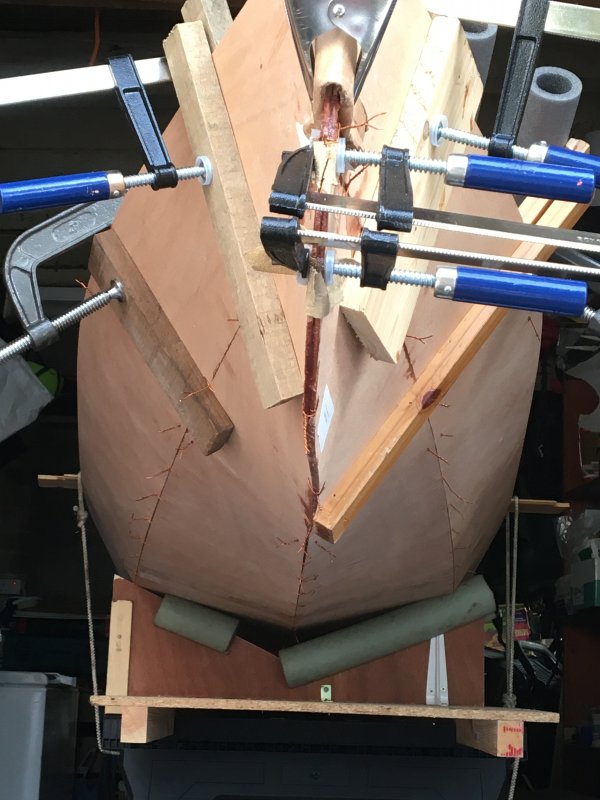

I had to really apply side and rearward forces on multiple clamps to get the keel-line straight, and I drilled holes for new stitches, etc, but whenever I took the clamps off it still twisted back to the bad shape. I finally got the line fairly straight, even with only one clamp, as you can see here;

But to do that I had to push the starboard side-panels up higher than the port, by about 1.2 cm.

I'm mystified why this works, given that the left and right sides were perfectly symmetrical when I did the puzzle-joints, the bulkheads & former were fully seated and their holes lined up all round, and the stern went together symmetrically and with no problems.

Anyway, I haven't re-drilled and epoxied anything yet. I propose to cut the top edge of the starboard side panel down to match the port before I do, and trim off the lower port side to match the starboard. I hope this won't make it hard to do the Hybrid decking and front hatch.

Does anyone have any alternatives or comments at this stage?

Last edited by kpalling (6 Sep 2020 9:44 pm)

Offline

#8 9 Sep 2020 10:53 am

- Phil

- Employee

- Registered: 8 Jun 2011

- Posts: 74

Re: Wood Duck Double Hybrid - Twisted Bow

Hi there,

We have sent you an email with detailed advice, but basically you need not to trim the panels, but you should cut the fillets working from the bow, cutting backwards until you get the twist out. It needs to be wired tightly together to get the correct shape, then you can tack-weld and fillet.

It is worth checking the panels are the right way round, bulkheads are in the right place etc as well.

Offline

#9 9 Sep 2020 12:55 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

I have read your last advice above, together with the separate email sent to me by Phil quoting the advice of both John at CLC and Eric who designed the kayak.

I had already tried these ideas, but I repeated it this morning: as I described above, I cut down the swoop of the bow from the top of the stem right back to the front bulkhead (past the bend in the keel). I did not cut between the side and bottom side-panels. I also checked that the bottom and side panels are symmetric and the bulkhead also, then I rewired the bow.

Try as I might, I cannot get the bend out as long as the two sides are aligned on the original holes. The port bottom panel has a bend in it which remains after cutting. I even spray-wetted it and tried to flex it straight. The starboard panel seems to be a weaker material, and just follows the port one when I rewire them. At this point all the holes align but the bend is still there! There seems to be no way to clamp the port bottom panel straight before I wire the starboard one to it.

Unless you have another suggestion, I repeat my proposal as a question:

If I push the starboard side up about 1.2cm above the port (see 3 photos back), the bend goes away. Can I then trim the panels to match without making the hybrid decking and hatch difficult for myself?

Thanks for you help, but I'm sure that if I leave the bend in, I'll be paddling round in circles!

Offline

#10 9 Sep 2020 8:18 pm

- Simpsonboater

- Member

- Registered: 26 Jun 2020

- Posts: 29

Re: Wood Duck Double Hybrid - Twisted Bow

Would it help to heat it up with a hot air gun to soften the epoxy where it has soaked in and set the bend?

Offline

#11 10 Sep 2020 2:31 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Thanks for the idea, Simpsonboater.

In fact I managed to get almost all the epoxy fillet off the plywood along the keel-line using my Multitool (not the soaked-in resin of course). I am now trying to straighten both the bottom planks by wetting them and clamping them to stiff battens in line with the keel centreline (one side at a time, I don't have room for the clamps otherwise). I'll leave it like that until tomorrow then remove the last batten and see how it matches up. If I think the resin is a problem, I'll try your tip with some hot air.

Right now I'm hoping for more ideas from the factory, and an answer to my proposal if the wetting/clamping doesn't work by tomorrow.

Last edited by kpalling (10 Sep 2020 2:34 pm)

Offline

#12 10 Sep 2020 2:58 pm

- Phil

- Employee

- Registered: 8 Jun 2011

- Posts: 74

Re: Wood Duck Double Hybrid - Twisted Bow

Kpalling,

I have spoken with Eric again and he is concerned that if you have twist in the bow, there will be something else wrong somewhere as generally action has a reaction. Before you make any cuts it is worth double and triple-checking the rest of the boat when you have the panels in the proposed position you cut them.

Thankfully you are making a hybrid boat, so you make the deck fit rather than relying on pre-cut plywood panels, as making the cut will alter the shape of the boat and would have an impact on the fit of the deck. Thankfully this is not an issue here.

Offline

#13 10 Sep 2020 3:18 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Thanks Phil. I will wait until tomorrow to see if my wetting/clamping efforts have improved things. I will then align as best I can (with or without an overlap), partially re-drill and re-wire, then triple-check the rest of the boat before trimming the panels. At that point I may have to re-wire again because the wires will pull better in the right direction if the panels don't have the big overlap. Then I'll do the epoxy-tacking and bow-fillet.

By the way, I got all the deck-forms out of the packaging and laid them in the boat today, just to see if that would highlight any mistake I'd made with the panels and bulkheads. Unfortunately for me they all fitted as they should!

I really appreciate the advice I've received, and I hope I haven't annoyed you with my insistence that the bend won't come out easily. I'll post again when I've re-tacked the bow.

Offline

#14 11 Sep 2020 6:42 pm

- Phil

- Employee

- Registered: 8 Jun 2011

- Posts: 74

Re: Wood Duck Double Hybrid - Twisted Bow

Kpalling,

Don't worry, this is what we do and we stand by our products the support we offer is all part of the service. I am just sorry it has taken so long to respond. You will get there in the end, it's just finding the best route for you.

The fact the forms all fit perfectly is a good sign! Please keep us in the loop and stay in touch.

Offline

#15 14 Sep 2020 9:10 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

OK, after the advice from Fyneboats, here's what I did. Having split the bow right back to the bulkhead, I then straightened each side, one at a time, by soaking the wood inside and out and then clamping the bottom plank to a wide, rigid, batten.

On the starboard side, the aim was to reduce the excessive curl along the keel-line that allowed the port side to push it over.

On the port side, the aim was to straighten the keel-line and take out the S-bend that had mysteriously shown up when I first started building.

After 12-hours soaking for each side, I was able to achieve a not-quite-perfect result. There is some deviation, but much less than before. Compare the picture below with the one on 14 August at 2:47pm. I decided to go with that, on the basis that any more fiddling would damage the wood too much. I did have to cut the top of the starboard side down by about 1cm at the bow and 0cm at the bulkhead.

So now I'm continuing with the build by preparing the hull for glassing. If I run into any more serious problems, I'll post under a different title. Thanks to everybody for helping, especially the FB guys.

P.S. I still don't have a clue as to how the twist appeared.

Offline

#16 15 Sep 2020 7:14 pm

- Pedro

- Member

- Registered: 30 Aug 2020

- Posts: 2

Re: Wood Duck Double Hybrid - Twisted Bow

Just a thought but is it possible one of the bottom panels could be back to front?

Offline

#17 16 Sep 2020 7:16 am

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Thanks Pedro. I have carefully checked all the panels against the manuals and I'm sure that isn't the case.

Offline

#18 8 Dec 2020 9:27 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

Two Months later ........ some of you may be wondering how all the above came out in the end.

I completed the kayak in the middle of November, painting and varnishing in our dining room because the weather was too cold and damp in the garage. Here she is at that point, with the hull-paint not yet finished.

I then installed a winch-system in the garage to store her. The black straps/ropes/pulleys at each end are connected to a small winch. The blue ropes with carabiners are just safety-straps in case the winch-system fails.

I then went away until the end of November, and until today the weather precluded me putting her in the water.

Last edited by kpalling (8 Dec 2020 9:31 pm)

Offline

#19 8 Dec 2020 9:30 pm

- kpalling

- Member

- From: Oswestry, Shropshire, UK

- Registered: 25 Jul 2020

- Posts: 14

- Website

Re: Wood Duck Double Hybrid - Twisted Bow

I finally launched her on the Llangollen Canal, between St Martins and Chirk, and had an hour's paddle with my wife. See the Boat Launches section https://forum.fyneboatkits.co.uk/viewtopic.php?id=703 for this.

Thanks to everybody who helped me out, especially the team at FyneBoats.

Keith

Last edited by kpalling (8 Dec 2020 9:59 pm)

Offline