You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 10 Jun 2020 6:59 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Painting/Varnishing

I have now finished my Waterlust, all bar the painting/varnishing (and rigging).

Having never painted a boat before I would really welcome some advice please, as there seems to be a bewildering amount of paint and varnish choice and quite a lot of 'lore' regarding its application - added to which unlike DIY paints, there are no instructions on the tins!

I have already varnished the interior with a standard varnish (7 coats) and it is OK, but not great. I can live with this as you don't see much of it..... But I want to do a better job of the deck and hull.

Deck:- I have purchased twin pack Epifanes polyurethane varnish with thinnner.

1. Should I thin this after mixing? If so what proportions?

2. For how long do you mix the two parts for before application?

3. Should I apply it with a brush or roller?

4. How long after mixing do I get before it goes off? ie How much do I mix at a time?

5. How many coats are required?

6. If more than one coat is required, is it best to sand between coats annd if so, how long do you leave it to harden before sanding and re-applying?

Hull:- I have purchased a standard marine primer, gloss enamel and thinner.

1. Do you thin the primer and enamel? If so what proportions?

2. How many coats of each? Do you sand between coats?

3. Brush or roller application ? (I had thought of foam roller followed by brush 'tipping' following earlier advice on this forum).

Any tips and tricks will be very gratefully received. Nothing is too basic!

Offline

#2 10 Jun 2020 11:37 am

- Bergen_Guy

- Member

- Registered: 6 Feb 2020

- Posts: 353

Re: Painting/Varnishing

I think - and but don't know - that it's not necessary to thin primer and varnish if you are applying these to a surface that has already been coated in epoxy. My understanding of the need for thinning was that it helps the paint /varnish penetrate into the wood. It's not going to do that if there is already a layer of epoxy doing that job. At least, on my waterlust I didn't thin either varnish (one pack) or primer (also one pack) I used a brush for the varnish and a roller for the paint.

Offline

#3 10 Jun 2020 12:33 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Painting/Varnishing

I admit I'm a newby to this marine stuff. My suggestions come from what I've read in books, or here on this or other forums where the topics are more specific than say painting a house, inside or out.

Generally, products sold are 'ready to use' for their intended purposes, though sometimes - depending on conditions under which they're being applied - a user may need to add thinner to make the finishing material more easily handled. If being applied by brush or roller, this means one ought to be able to proceed with the application while keeping a 'wet edge' between the coated and uncoated surface. This keeps a hard line from forming where fresh, wet finish is applied over an edge that's been left too long so it's begun to harden or cure.

On the other hand any additives should be used with moderation as anything going into the can that's not intended to stay on the finished surface must leave somehow, which will slow dry time and may also impact film thickness.

When in doubt I look first to the manufacturers' web pages if specific instructions aren't included on their products labeling. Short of that, they may offer a support function on their websites. Otherwise it's the forums like this one, the one CLC maintains, or the feistier one over at Woodenboat.com where the user bases hold more experience than I can ever lay claim to.

The only truism I can offer up that's applicable under ALL circumstances is: adequate preparation is 99% of what's needed for a successful finish. That seems inescapable.

Offline

#4 11 Jun 2020 8:54 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

For anyone else looking for answers in relation to Epifanes products I found this after much searching.

https://shop.swiss-composite.ch/shop/re … hure-e.pdf

Offline

#5 11 Jun 2020 10:05 am

- Ian

- Employee

- Registered: 24 Nov 2014

- Posts: 103

Re: Painting/Varnishing

If you haven't used a twin-pack system before, be aware that the solvents in it will dissolve foam brushes and rollers (bristle brushes are fine, but use a good one that doesn't drop bristles). If you work quickly, it's possible to get a complete coat on (I use a roller and tip off with a brush, but everyone has their own preferred method). Best keep a spare foam brush/roller handy and use it as soon as the first starts to feel like it is sticking, otherwise it starts to leave flecks of foam that have to be sanded out. You can get solvent-resistant rollers -- they still dissolve, but they give you more time. Make sure you use mixing pots that are suitable for twin-pack, or your varnish will suddenly start pouring out after ten minutes or so when it has dissolved the bottom of the pot (I speak from experience!).

For the drying times and other technical details, you can download the product info PDF from the Epifanes website:

https://www.epifanes.nl/uk/the-epifanes … -filter-55

It also recommends six coats in total, but that is for coating bare wood. The first two coats are thinned to improve penetration into the wood, but the epoxy is basically doing that job so I think you can start with the third coat.

Offline

#6 11 Jun 2020 1:14 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

Thanks very much Ian. Huge help.

A couple of questions please:-

1. Is twin pack suitable for the deck of a Waterlust? The reason I ask is because one of the websites I looked at said it wasn't suitable for a 'flexible' surface. My boat deck certainly 'flexes' when I sit on it!

2. I only have enough for two coats. Will that do? Can you put ordinary varnish on top if necessary?

Offline

#7 12 Jun 2020 9:00 am

- Ian

- Employee

- Registered: 24 Nov 2014

- Posts: 103

Re: Painting/Varnishing

1. I haven't actually seen a Waterlust in the flesh yet but I'd be very surprised if the deck flexes enough to be a problem. I think what you read was probably referring to spars, because the spars of some rigs are designed to flex quite significantly. The clearest example is in photos of the Outrigger Junior. The spars are straight lengths of timber but are visibly curved in use, to form the right sail shape.

2. You can certainly put single-pack varnish on top of twin-pack. It's sometimes recommended because the single-pack is easier to touch-up any wear (it saves carefully measuring and mixing tiny amounts). The only thing you can't do is put twin-pack over single-pack, because the solvents will blister the single-pack coating.

Offline

#8 12 Jun 2020 9:51 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

Thanks Ian. I'll crack on with the two part varnish.

One other question please. I bought some Boatguard Marine primer (https://www.paints4trade.com/boatguard- … 3850-p.asp) The first coat went on really well (with a roller). It says it is re-coatable after 50 minues, however, the second coat isnt going on at all well. It seems to be very thick in some places and not adhering at all in others. Could it be that this is the wrong primer for epoxy or should I leave it 24 hours?

Offline

#9 12 Jun 2020 10:15 am

- Ian

- Employee

- Registered: 24 Nov 2014

- Posts: 103

Re: Painting/Varnishing

I'm not familiar with that primer but I'd try leaving it a bit longer. Drying times are usually temperature-dependent (or humidity-dependent, for some paints) and they usually quote the drying times at 25C or similar, so it will probably take a bit longer.

Offline

#10 12 Jun 2020 11:41 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

Thanks Ian. I'll leave it until tomorrow.

Offline

#11 13 Jun 2020 1:32 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Painting/Varnishing

Martin did you scuff up the epoxy you then applied primer to? That seems to be a universally recommended step, either to use sandpaper to remove the cured epoxy glaze and any possible amine blush that may be present or something like what's available here in the US as a non-woven abrasive like ScotchBrite.

I'm using the Kirby Paint products on my build. Spoke with George Kirby earlier this week about whether wet-sanding their marine primer was a good idea or not. He'd previously said the epoxy wet-scuff with Scotchbrite was essential for a reliable bond, then later said he didn't think there'd be any problem wet-scuffing or -sanding the dried primer. Doing it wet does keep the dust produced to a minimum as it becomes a slurry that can then be mopped up quite easily. Done dry you'd best be wearing a respirator & vaccuum often or the dust will get out of control!

It's been six days since I did the first roller-applied coat of primer on my cockpit. Did a sanding test - wet vs. dry - after 24 hours, found sanding wet w/ 220 grit paper was faster, seemed to require less effort and produced a smoother surface than what had been done dry. Will be wet-sanding the entire primed cockpit today, hope to get a second coat on once it's dried thoroughly so the next coat goes on well.

That Boatguard Marine Primer sounds a lot like what Kirby's puts out, what I'm using. The 'fast-drying' is a marketing phrase I think, it's still an oil-based product and will need enough time for the solvents to evaporate, then the resin binders need to oxidize before it's fully 'cured' and ready for sanding. You put a second coat on over epoxy before the first has cured I think the solvents will affect the first coat, maybe be why you saw yours coming off in spots or sticking together making a thicker layer than what you'd have seen otherwise.

That's the biggest advantage of the two-pack formulations. The catalyst - why the products are sold for us to mix before use - create a chemical reaction that vastly accelerates the cure. Resulting finish is ready sooner and is much harder, more resistant to damage than the older, solvent based products could ever manage.

Last edited by spclark (13 Jun 2020 1:44 pm)

Offline

#12 13 Jun 2020 7:54 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

Thanks SP. Yes I did give it a good washdown with a Scotchbrite type pad with plenty of soapy water. However, Ian was right. It was the temperature which was the issue. I think the outer crust had hardened leading me to believe that it was safe to re-coat, especially as I had left it more than the required 50 minutes. However, it was nothing like 25C here and having left it a few more hours all was well. My only problem now is that it clearly takes more than the 1 litre to cover the bottom 3 times (2 coats weren't enough) and I have run out of paint! More promised for Monday though so I'll take a weekend break.

Thanks for all the help.

Offline

#13 14 Jun 2020 2:51 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 478

Re: Painting/Varnishing

That'll happen with oil-based products - they can 'skin over' leaving you to think they're dry & hard but underneath the stuff's still softish, needs more time before full hardness is reached.

Yesterday I finished wet-sanding the Kirby's Marine Primer I'd applied to my Waterlust's cockpit seven days ago. There were a couple of spots where the stuff'd pooled that I hadn't noticed. Those got scraped clean then lightly sanded, and this morning what was left behind resists fingernail-scratching as well as the stuff that'd been applied more thinly & left to dry all that time.

I'll be applying a second coat of the same stuff later today so have the garage space bumped up to 75°F / 24°C for a couple of hours to ensure whatever moisture might have been captured by the primer during wet-sanding will have evaporated by the time I've run some errands & can get back to it for re-coating.

Spoke with George Kirby earlier this week after questions were raised on the CLC forum about wet-sanding high-build primers like Kirby's. The talc they may contain is interesting stuff when it comes to absorbing water, reports from others who'd had issues with high-build primers gave reason to do a little more research before going the wet-sand route. George indicated he couldn't think of any reason not to wet-sand as long as the primer'd been applied thinly - as suggested on the label - and given sufficient time to dry.

So I did a small area both ways using 220 wet/dry 3M paper, found the wet sanding went faster with less effort and faster clean-up. No respirator needed either, or vacuum for removing copious dust produced by dry-sanding, and the paper lasted longer.

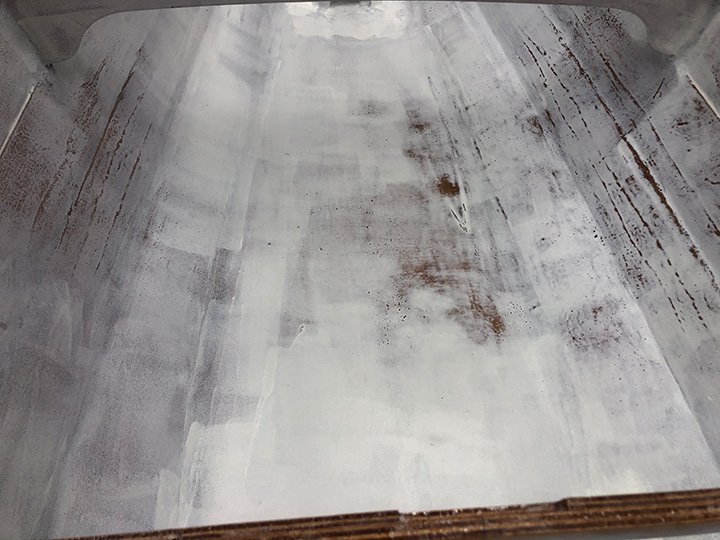

Results shown here; dry side on left, wet-sanded on right followed by close-up of dry side then the area done wet:

I'm happy with how smooth this first primer coat's turned out after wet-sanding, have great expectations for how the final surface will be when it comes time to apply the finish coats of paint. Same for the outer hull which'll be getting the exact same treatment once that time comes.

Offline

#14 15 Jun 2020 2:00 am

- DerekD

- Member

- Registered: 12 Aug 2013

- Posts: 33

Re: Painting/Varnishing

It's only paint. Paint it.

Offline

#15 15 Jun 2020 3:13 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 348

Re: Painting/Varnishing

Thanks SP. As always, I found your post interesting and helpful.

Offline

Pages: 1