You are not logged in.

- Topics: Active | Unanswered

#1176 26 Feb 2023 5:49 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

MartinC do you look in much on a forum @ Woodenboat.com?

There're some wonderful posts by a fellow who's currently in Poland, used to live and explore not far from me here in the US. He's a talented writer as well, had articles featured in the Small Boats magazine from time to time.

Here's are some links to threads you may enjoy:

http://forum.woodenboat.com/showthread. … ath-s-Door

Offline

#1177 27 Feb 2023 8:28 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Thanks SP.

I look forward to some pre-season inspiration.

Offline

#1178 27 Feb 2023 5:55 pm

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 136

Re: Waterlust sailing canoe in Norway

Hello Martin et al -

I have been thinking about mats/flooring for the Waterlust as I find that the varnished wood is pretty hard on the knees. Have any of you thought about the material that CLC sells for the purpose: https://www.clcboats.com/shop/products/ … craft.html ?

This looks like it would be great, but quite expensive. I wonder if one could cut up and glue down a yoga mat and achieve the same functionality. Other than the cost, my main concern would be durability -- I tend to get a lot of sand and grit in the bottom of the boat, and I would think a mat would have to be pretty tough to withstand that sort of abuse...

Last edited by Chuck (27 Feb 2023 5:57 pm)

Offline

#1179 28 Feb 2023 7:47 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Hi Chuck. I haven't come across the CLC product. I used 'closed cell' foam for the sleeping area aft of the cockpit to reduce condensation.

Foam comes in 'open cell' and 'closed cell' form, and having looked online I see that yoga mats can be made of both. You would want the 'closed cell' type as it repells water, but apart from that I think a yoga mat would be fine.

Be careful about the glue you use. If you use contact adhesive you would need to sand off any varnish first as it will be dissolved by the glue! In areas where the mat is held in place by the boat's hull (like the floor) I would use clear silicone (bathroom) sealer as this will hold the mat in place adequately and if/when the mat is worn out it will be much easier to remove.

Offline

#1180 1 Mar 2023 3:10 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Have any of you thought about the material that CLC sells for the purpose: https://www.clcboats.com/shop/products/ … craft.html ?

This looks like it would be great, but quite expensive.

I got their sample pack a few years ago, looks super but as you've said it's really pricey stuff. I'd opt for the yoga mat idea myself, with a mind to changing it out when it begins to suffer from the abrasions of use.

And for you Chuck here's a link to a post on the WoodenBoat Forum asking about jibs fitted to balanced lug rigs:

http://forum.woodenboat.com/showthread. … with-a-jib

- which ought to be of interest to you. Look in often, I'm sure there'll be further posts added over time.

For securing mat material the silicone idea MartinC suggest ought to work but keep in mind silicone contamination of epoxy is really hard to overcome should further epoxy ever be needed. My own thoughts turn to what's referred to as 'automotive' or marine Velcro. It's not like the hook & loop original stuff, instead both halves are the same and engineered to 'nest' into one another to form a strongish bond yet still be fairly easy to pull apart when needed. The pressure-sensitive adhesive used to stick it down is rubber-based and ought to play well with either varnish or paint over epoxy.

(Somehow despite my recent post I never received notice of these latest posts so hopefully this one will rekindle the forum's notice of new material function....)

Offline

#1181 4 Mar 2023 6:04 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Sprayhood nearly complete with some needlework help from Mrs C. Just the sealing of the seams and a slight adjustment to the 'opening'. (It's a bit tight!).

Looking forward to getting on the water but snow forecast for next week so no chance for a while.

Offline

#1182 7 Mar 2023 12:42 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Back to ballast!

Although Gaia sailed very well last year in some quite high winds, the 15kg steel daggerboard is a bit of a monster to raise and lower and with an eye to my trip to Holland (quite shallow), I don't want to be struggling with it if it is not now necessary.

As well as the steel daggerboard I have a port and starboard 8kg lead weight in the cockpit and 18kg of water ballast and 18kg of lead ballast in the front locker.

The main purpose of heavy daggerboard was to assist re-boarding after a capsize, as in the early days without any ballast I found it to be impossible.

I would be very interested to hear what weight and position of ballast you have all now settled for.

Offline

#1183 9 Mar 2023 2:23 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

I can see how a 33lb (2.2kg) 'board would be a little cumbersome to deal with once afloat MartinC, yes indeed... my 'inlet' 9 lbs of lead (a tad over 4 kg) makes the 'board quite the hand full just storing it over winter.

I've yet to test its utility value when afloat but rest assured I'll relate my experiences here once the opportunity's presented itself early this season.

Earlier in this thread I described my 'removable ballast carrier' onto which I can secure various, similar lead 'bricks' into the bottom of the storage locker between mast pockets. In all I cast six bricks, varying from 17lb to 27 lbs. Milling the lightest to a thickness appropriate for epoxying into by d'board lightened it up a little, but the other five I simply 'knocked the edges off' so they'd be less likely to degrade the nylon webbing I fitted to the carrier that will secure each one in place in the event of a capsize.

This all last season additions, both yet to be tested once afloat. The d'board will be a constant, the removable weights something to explore when I'm soloing. Last June I found having a 165lb (75kg) 'movable ballast' crewmate aboard vastly improved stability!

Of course we also had the amas package fitted, proved their utility when gusts caught the main.

(Somehow once again I missed getting word of your latest post; no idea why. I look in here now fairly frequently, specifically because I'm looking too see if there might be something I've missed....)

And for you MartinC there's a new thread on that WoodenBoat forum by Mr Tom about his adventures in one of our Great Lakes up North: http://forum.woodenboat.com/showthread. … mall-Boats

Offline

#1184 9 Mar 2023 2:37 am

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 136

Re: Waterlust sailing canoe in Norway

Hi Martin: I have four ballast pockets in the main storage compartment. Each will hold a 30 pound mass of lead. So, 120 pounds total if fully loaded. If I was sailing alone without the amas, I would definitely put in the 120 pounds. With the amas, I'm not sure yet as I have not tried it much. When sailing with my usual lightweight crew, I just use two 30 pound pieces of lead in the ballast pockets furthest forward. I have reboarded the swamped boat with this ballast fairly easily on my own.

Another topic for the crew: Have any of you thought about a tabernacle for the mast to support folding it down? I have a couple of low clearance bridges that it would be nice to pass under, and so far I have been too scared to try unstepping the mast while underway

Last edited by Chuck (9 Mar 2023 3:03 am)

Offline

#1185 9 Mar 2023 8:50 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Thanks both. It would seem that my 114lbs will be enough without the steel board. I'll give it a try as soon as the weather improves.

Guy:-Your experience with ballast would also be interesting.

Chuck:- I spoke to Dylan about a tabernacle in the early days of my build. He felt it would not be a problem, but in the end I reduced the size of my main mast and rig so that I could lift it out whilst underway (and store all the rigging inside the boat when travelling). You are a braver man than me if you are going to try and lift the original mast in and out whilst underway!

Your challenge will be to make the tabernacle 'cheeks' strong enough to withstand sideways forces when the mast is halfway up/down. I had a wooden tabernacle on my last boat and even with stays and shrouds I had to make a number of reinforcing repairs during its lifetime.

Offline

#1186 12 Mar 2023 8:10 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

I have been thinking about Chuck's enquiry about installing a removable waterproof bulkhead to seal off the back part of the boat.

As I have tried and failed to find a watertight hatch online which is the right size, (and I think a bespoke one would be beyond my capabilities), I wondered if a tarpaulin held in place with Velcro would be sufficient. I don't know know how watertight Velcro would be, but might it hold the water out for long enough to prevent swamping? Is there a watertight Velcro equivalent out there?

Any thoughts anyone?

Offline

#1187 12 Mar 2023 2:54 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

There's a 'marine/automotive' Velcro made by 3M available here that might do what you want MartinC. It's not 'hook & loop' instead both halves are the same material, designed with little ball-ended 'whiskers' that, when pressed together, yield a very strong closure:

Only form I've seen is pressure-sentive adhesive backed, but I suppose it could be stitched in place with the proper stuff. I doubt it's watertight though; given any difference in inside vs. outside pressure there's gonna be water going through the joint.

If you can't find it over there, gimme a shout & I'll send you some.

Meanwhile back in the basement (while the snow once again leaves something for the plow to push up into my driveway) I'm messing with various epoxies in my endeavor to add a hinge aspect to my Waterlust's aka:

Idea being to reinforce the cut ends of my aka with some feature that will counter the twisting the aka has to endure when in use. I doubt the laminated marine ply will be up to the task so I'm planning to add a 'tongue & groove' component secured to the cut ends that'll allow folding but lock rigidly together once the amas are lowered and the fiberglass hinge/lock mechanism's secured.

On another, related front, there's word of a new Harris / CLC inspiration some are calling Waterlust II:

https://www.clcboats.com/life-of-boats- … igger.html

Will be watching this one with obvious interest....

Last edited by spclark (12 Mar 2023 2:55 pm)

Offline

#1188 13 Mar 2023 4:55 am

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 136

Re: Waterlust sailing canoe in Norway

Wow, that Tallulah canoe is amazing, SP! I wonder what sort of speeds they can reach with it.

Does this mean you are doing the Everglades Challenge next year?

![]()

Last edited by Chuck (13 Mar 2023 5:21 am)

Offline

#1189 13 Mar 2023 4:58 am

- Chuck

- Member

- Registered: 24 Nov 2020

- Posts: 136

Re: Waterlust sailing canoe in Norway

In other news I've finished my lazy jacks and gotten the hardware in for the jib halliard and tack. It is definitely going to be a challenge to find real estate on the deck to mount the turning blocks and jib cleats. I had to make a mast extension to get the additional six inches I needed to find a place out of the way to put the lazy jack blocks above the main halliard dumb sheave.

I've also put in thicker line for the rope steering (~3.5 to 5.5 mm) and in the shop it feels like it will be much easier to grip and use.

And, I've just put in an order for the Selway Fisher sail building manual, so I have fewer and fewer excuses to not get that jib made...

I've been trying to find places on the net that say what tacking angles might be expected from a balanced lug. Not much I can find, but it looks like ~100 degrees can be reached. My GPS trace still shows tacking angles closer to 125 degrees, so I guess I still haven't yet found the problem with my rig.

I'm finding that with the boat already sailable with a couple of seasons in, it is a lot easier to get motivated and finish these smaller projects.

Last edited by Chuck (13 Mar 2023 5:45 am)

Offline

#1190 13 Mar 2023 12:22 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Does this mean you are doing the Everglades Challenge next year?

Glad you added the ![]() there Chuck.... I'll be there, but only in my dreams yeah.

there Chuck.... I'll be there, but only in my dreams yeah.

I've also put in thicker line for the rope steering (~3.5 to 5.5 mm) and in the shop it feels like it will be much easier to grip and use.

Ought to help. Curious how hiking out will work with that; I'll put off my experiments in that direction, I have enuf on my plate with the hinged aka and getting more tiller time out on the water once the ice's out and water's a tad closer to 60°F than presently here'bouts.

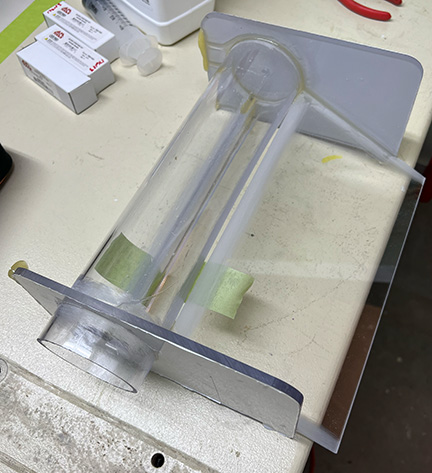

After more than a decade I've finally gotten 'round to fabricating a new ship chute for my venerable INCA 10" jointer/planer. The original came with the planer back in the late '70's, getting too long in the tooth to trust in use and the mod I'd added for connecting to my dust collector was on the wrong side for convenience. So I've built one out of polycarbonate tube and sheet, with the aid of G/Flex epoxy (works GREAT on many plastics!) and some copper wire -

Stitch & Glue has uses other than with marine ply it turns out!

Offline

#1191 13 Mar 2023 2:13 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Well done Chuck and SP! That's a really impressive piece of work on the planer chute SP.

Thanks for the details of the Velcro alternatiove SP. I am giving this more thought before starting on this as there are so many options. I am currently thinking of an epoxy ply (6mm) removable door held in place with a magnetic shower door fitting https://showersealuk.com/mag023-magneti … creen-seal.

By fitting the panel on the outside of new jamb it has the advantage of becomming tighter and tighter as the cockpit fills with water. You you think it will work?

Offline

#1192 13 Mar 2023 2:48 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Better than anything fabric-like, yes! Just pay attention to flexing that could distort the gasketing's seal around the edges.

Interesting range of products that outfit markets MartinC, thanks for the link!

I know of similar products sold here but typically not directly to consumers. Be curious to hear what they answer to a question about US availability might be....

Last edited by spclark (14 Mar 2023 1:04 pm)

Offline

#1193 15 Mar 2023 2:30 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Got that polycarbonate chip chute done today, mounted to the planer for a test run:

https://www.youtube.com/shorts/A-0lsXYOZwM

Works GREAT!!

Offline

#1194 15 Mar 2023 6:16 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Looks great SP!

Wish I had one.

Offline

#1195 22 Mar 2023 11:59 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

http://forum.woodenboat.com/showthread. … ling-canoe

Of interest, for your enjoyment!

Offline

#1196 2 Apr 2023 7:37 am

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

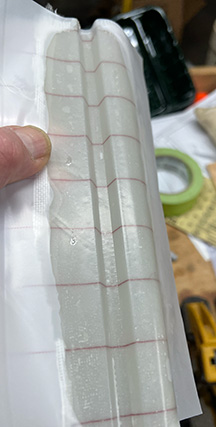

I have been thinking more about a watertight removable hatch to seal off the rear and have come up with the following which I think will work.(Please foregive the rough and ready workmanship as this is the result of an evolving process, and some ideas didn't work and had to be filled/repaired!).

The frame fits behind the frame to the rear of the cockpit which it overlaps and it will be epoxied to it and to the floor and 'roof'. I have made the frame as slender as possible so it takes up a minimum of usable space. The plywood is 12mm. Chuck's sash window catches are used on three sides but not on the floor as I have to sleep on this! I am using cheap interlocking garage floor mats which are about 10mm so this takes up the thickness of the frame on the floor. I am thinking about a second (round section rubber) seal in a groove around the edge of the hatch cover but I think I will test the watertightness of this first.

I have had concerns about the boat floating too high in the water when capsized but I think this can be overcome with the ballast I now carry. Time will tell!

Offline

#1197 2 Apr 2023 10:20 am

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Ought to work MartinC, the principal is the same as what CLC uses for the flush hatch on deck up front. Those sash latches you had Chuck supply, or you sourced from over here? Are they brass, or just plated steel? Those are common here, from several sources, some better than others....

An e-mail I received last week from a company here that provides all kinds of marine-grade stuff of boating fabrics & sewing supplies touts a type of self-adhesive non-slip material that may be of interest here:

https://www.sailrite.com/Marine-Foam-Fl … ive-Backed?

I've seen those garage 'tiles' too, suspect they're thicker than this stuff. Can you post a link to where you sourced yours? Again what's available here may or may not include the same stuff.

As for your workmanship, there's no lack in your trial & error methodology! If that 12mm ply's stiff enough the concept is a sound as your evident workmanship.

Weather's warming - slowly - here now though the changes have brought some pretty violent storms too, sadly. Our climate and the seasonal shifts we endure I don't think have an equal to what your island nation sees.

Last edited by spclark (2 Apr 2023 10:21 am)

Offline

#1198 2 Apr 2023 3:52 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Thanks SP.

I sourced the window catches from a UK company over here. They were advertised as brass but clearly aren't. Strangely they aren't ferrous and are too hard for aluminium. I guess they originated in China and are some kind of strange alloy, but I think they will do the trick as I am not asking much of them.

These are the floor tiles. They are not self adhesive and if you look closely you can see the interlocking puzzel joints. I don't know how long they'll last but you get 6 big squares for £16 so they can easily be replaced.

https://www.halfords.com/tools/garage-e … 36870.html

Re. The weather:- Our climate down here in the south east of the UK is pretty tame compared to yours, but I have been able to take advantage of one of the wettest months for many years to do the boat jobs in the garage. It will be great to get out on the water again though. Another couple of weeks I guess - It is not uncommon to have snow showers in April!

Offline

#1199 2 Apr 2023 4:06 pm

- spclark

- Member

- From: "Driftless" Wisconsin USA

- Registered: 19 Mar 2020

- Posts: 465

Re: Waterlust sailing canoe in Norway

Brass-plated methinks, likely a zinc alloy casting. What we affectionately refer to as 'pot metal' here. Should be OK in fresh water exposure, maybe not too long-lived in salt. But suitable for a test? Sure!

There is such a thing as solid bronze sash locks, but the price will take your breath away: https://www.houseofantiquehardware.com/ … -sash-lock

Much that's advertised as 'brass' or 'bronze' isn't solid, just plate.

Those interlocking matts look nice, particularly a pair for £20! Lots of options here too: https://www.americanfloormats.com/inter … age-tiles/

If my garage floor wasn't so badly spalled from the former owner's lack of maintenance (freeze-thaw salt-laden 'drippage' in winter plays hob with concrete!) I'd be inclined to invest in doing mine.

Spring here means tornados. Sometimes quite a few, as over the past few days south to north across the eastern part of the US. We're likely to see snow too, sometimes in mid-April where I am now, but the grass IS turning green and the Robins & Redwing Blackbirds have been back for a couple of weeks in force so it won't be long before decent sailing weather returns once again.

Last edited by spclark (2 Apr 2023 4:12 pm)

Offline

#1200 3 Apr 2023 2:14 pm

- MartinC

- Member

- Registered: 3 Apr 2020

- Posts: 341

Re: Waterlust sailing canoe in Norway

Here is the finished/fitted article. I am pleased to say it is a nice tight fit and although it won't stop every drop of water, I think it will prevent a swamping for long enough for the pump to pump out the cockpit.

I sealed off the circular holes in the boat's frames with ply bonded with Sikaflex so water can't bypass the hatch. It is all a bit messy down there but tidying up and re-varnishing will have to wait until the end of the season.

Offline